We help industrial companies increase efficiency

We are imk Technologies.

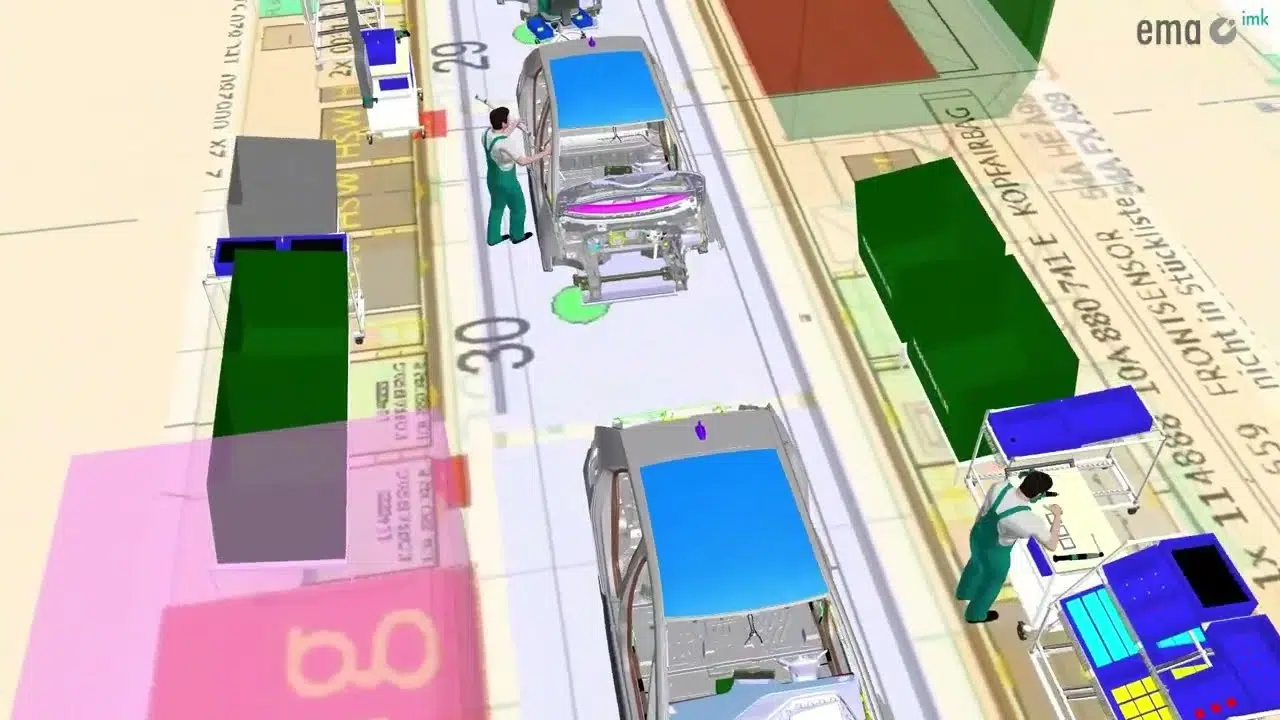

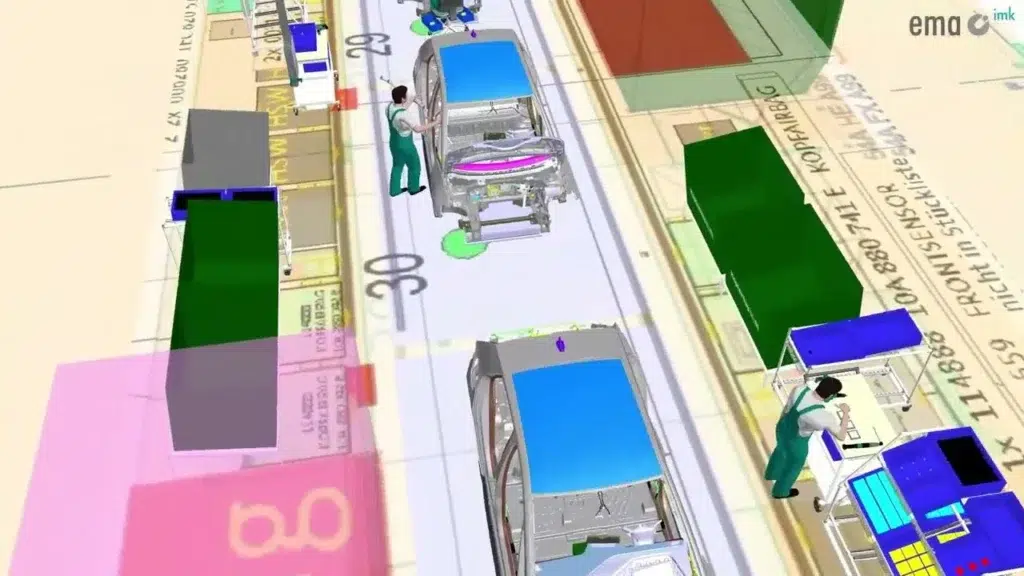

Our ema Software Suite elevates efficiency by optimizing running routes, material flows and ergonomics.

Your outcome – significant increased operational efficiency, while reducing workers compensation claims.

ema Software Suite

explained in 1 Minute

ema focuses on the human as workers. We will show you how we can get the most out of every production.

We want to change the world of factory planning together with you.

increase productivity

25%

reduce planning time

35%

save costs

>100.000$

save resources

25%

less travel

60%

Virtual Planning. Real Value.

choose your

ema Modul

ema Plant Designer

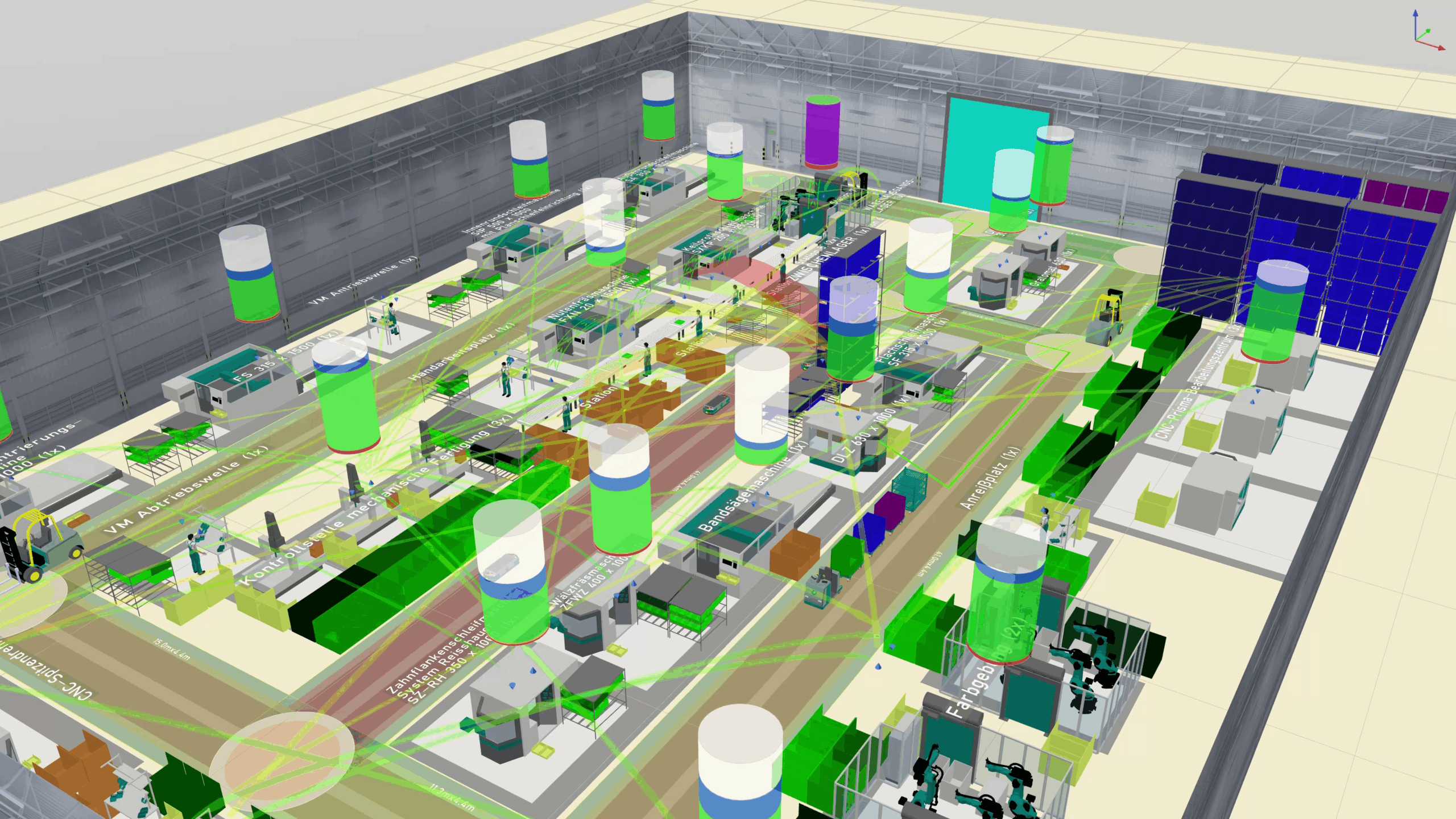

Integrated Factory & Material Flow Planning

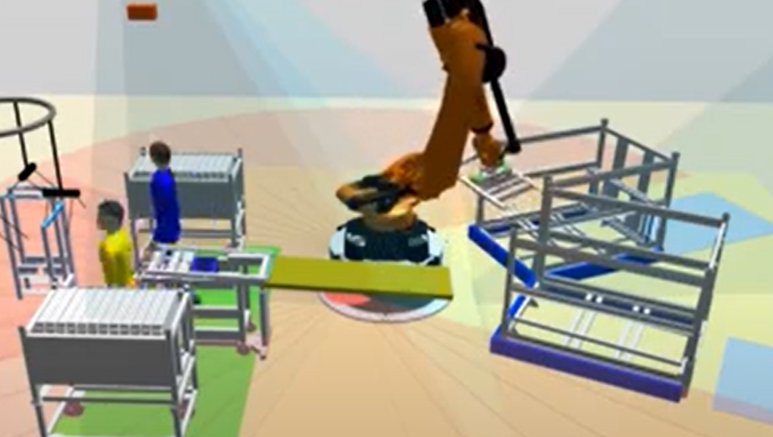

Learn moreema Work Designer

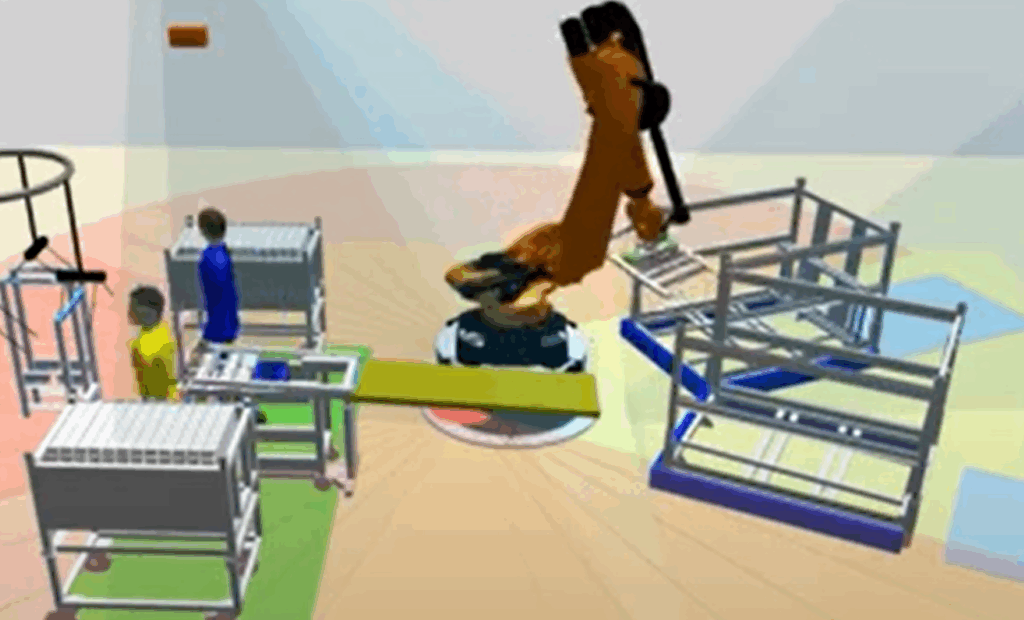

Holistic workplace & process design

Learn moreOur Customers

Plant Designer & Work Designer

Flexible Pricing Options

ema Plant

Designer

$720 / month

ema WD

Base

$590 / month

ema WD

Performance

$1.690 / month

$ 2.790 / month

ema WD

Professional

*prices depend on license type (nodelocked/floating) and lease dutation

Optional functions

all are included in Professional

About imk Technologies

Founded in 2010 in Greenville, South Carolina, imk is an international provider of engineering and consulting services for factory planning, ergonomics consulting and workplace design with a German heritage. Our founder and CEO of imk Health Intelligence Dr. Jens Trepte and CEO of imk Industrial Intelligence Dr. Lars Fritzsche represent the company in Germany. Furthermore we are

a developer and manufacturer of medical and transmission technologies.

The imk Group operates in the Industry and Healthcare sectors.

All about

Digital factory planning

What is the digital factory?

The term digital factory (or digital factory planning) is a popular buzzword these days, suggesting progressiveness and zeitgeist in a world of increasing digitalisation.

But what is behind this term?

In principle, the term “digital factory planning” speaks for itself. The term “digital twin” is also frequently used. In short, this is a fully digitalised image of an existing (brownfield) or future (greenfield) production facility. With appropriate software solutions, the digital twin of a factory can be planned and tested virtually before “real” production begins.

In this the WEKA Industry Media learn more about the terms “greenfield” and “brownfield”.

The digital factory can also be described as a comprehensive network that includes digital models, methods and tools.

But digital factory planning is more than that – it extends from the initial idea through the entire planning process to the commissioning of the factory plant. In addition to production planning, logistics planning, route and material flow planning and personnel planning also play a role.

The added value of a digital factory

You are probably wondering what added value a digital factory brings and whether it is worth the effort and cost. The obvious advantage at first glance is that processes can be simulated, resources can be managed efficiently and the available space and energy can be optimally utilised. Holistic planning takes place in the digital space. It is also much easier to control and improve all processes and resources.

Another factor in favour of a digital twin is the acceleration of planning processes and the reduction of planning errors. This not only saves time during planning, but also costs for physical trials.

Investing in a digital twin is also worthwhile for brownfield projects, as existing production processes can be examined and optimised to create a holistically improved process.

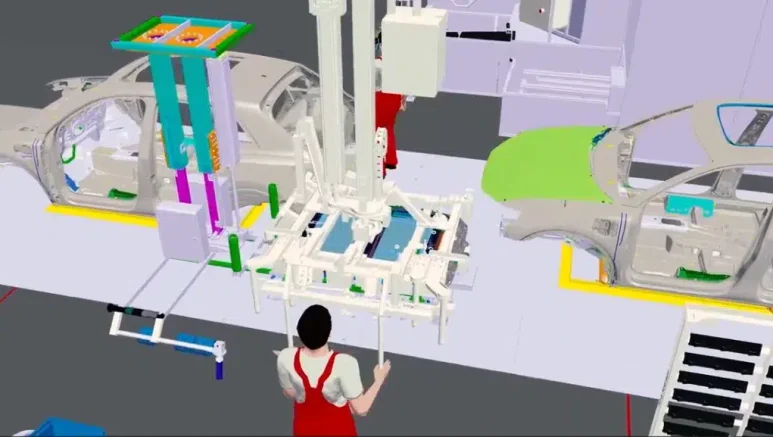

Visualising the factory using 3D simulation enables you to present your ideas and plans transparently and comprehensibly. Visualising all processes in 3D in advance provides one thing above all – planning security

Factory planning software as a solution

Are you ready to optimise your production processes and digitally transform your factory? Use our holistic factory planning software to set up, simulate, optimise and visualise your production as a digital twin.

The ema Plant Designer enables simple, fast and precise planning and evaluation of production processes with the aim of developing lean and highly efficient production.

The software offers the best of the worlds of simulation and value stream and delivers reliable results on workplace utilisation including bottleneck analysis, production costs, throughput times and critical paths, buffer spaces and production areas, material flows and resource consumption – regardless of the type and size of the use case.

The ema Work Designer can be used to plan, simulate or optimise workstations and workflows in detail. The detailed process simulations are created with our unique parametric human model. This means that the structure itself and changes can be made very quickly. Our digital twin also provides you with all the important key figures and results for detailed planning. From MTM-UAS®-certified target time determination and detailed ergonomics analyses (e.g. according to EAWS or NIOSH) to route diagrams or cost analyses, up-to-date data is always generated fully automatically as a basis for decision-making.

The ema Work Designer and ema Plant Designer modules are seamlessly interlinked and form our building blocks for your digital factory planning.

Contact us now!

Prof. Dr. Lars Fritzsche

CEO

Dr. Sascha Ullmann

Head of Customer Success